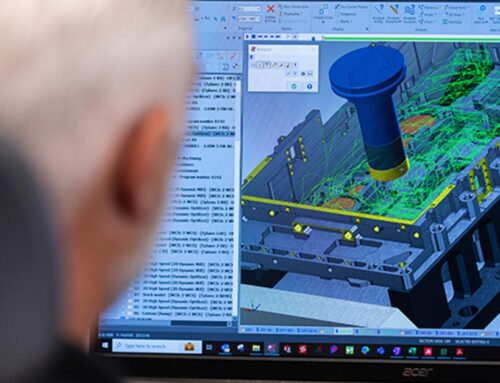

Unleash Your Manufacturing Potential with Mastercam

In the world of modern manufacturing, precision, speed, and efficiency are paramount. This is where Mastercam steps onto the stage as a powerhouse software solution that empowers businesses to unlock their full potential. Whether you’re in aerospace, automotive, medical devices, or any other industry, Mastercam offers a comprehensive suite of tools designed to streamline your processes and enhance your productivity. In this blog post, we’ll dive into the benefits of Mastercam and how it can revolutionize your manufacturing operations.

Precision Redefined

One of the standout features of Mastercam is its unparalleled precision. The software integrates advanced toolpath algorithms that enable precise control over machining operations. This translates to components with tighter tolerances, reduced rework, and higher quality end-products. Whether you’re working with complex 3D geometries or intricate multi-axis machining, Mastercam ensures that your final product aligns perfectly with your design specifications.

Streamlined Workflow

Mastercam is renowned for its user-friendly interface and intuitive workflow. With its robust CAD capabilities, you can effortlessly create, edit, and optimize designs within the same environment. This seamless integration eliminates the need for back-and-forth between different software applications, saving valuable time and reducing the chances of errors during data transfer.

Versatility in Machining

From basic milling to advanced multi-axis machining, Mastercam covers a wide spectrum of manufacturing processes. It caters to the needs of various industries, whether it’s creating intricate molds, precise tooling, or complex mechanical components. The software’s extensive library of toolpath strategies ensures that you have the right tool for the job, regardless of the complexity of the task at hand.

Rapid Prototyping and Iteration

In today’s fast-paced business environment, the ability to quickly iterate and prototype is crucial. Mastercam facilitates rapid prototyping through its simulation and verification tools. Before sending a job to the shop floor, you can simulate the entire machining process, identifying potential collisions, toolpath inefficiencies, and other issues. This not only saves time and material costs but also reduces the risk of damaging expensive machinery.

Enhanced Efficiency and Cost Savings

Mastercam is a strategic investment that yields significant long-term benefits. By optimizing toolpaths and reducing material wastage, you’ll experience lower production costs. Moreover, the software’s efficient programming and machining strategies lead to shorter cycle times, increasing overall throughput and capacity without compromising quality.

Continuous Innovation

The world of manufacturing is constantly evolving, and Mastercam is no exception. Its developers consistently release updates and new features that incorporate the latest industry trends and technological advancements. This ensures that your manufacturing processes stay at the cutting edge, giving you a competitive advantage in the market.

Mastercam is not just a software solution; it’s a transformative tool that empowers manufacturers to push boundaries and exceed expectations. With its precision, streamlined workflow, versatility, rapid prototyping capabilities, cost savings, and commitment to innovation, Mastercam stands as a cornerstone for businesses seeking to elevate their manufacturing operations. Embrace Mastercam and unlock your true manufacturing potential today.

Contact our team HERE!