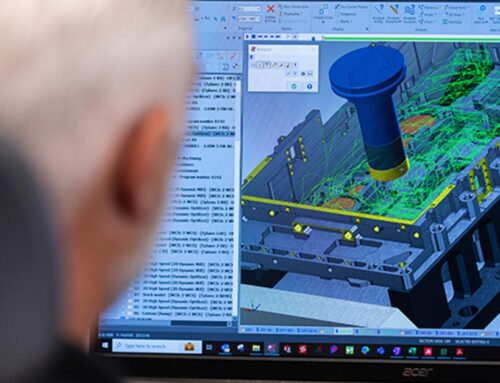

Mastercam Mill 2D or Mill 3D

For our 3-axis customers, a question that comes up frequently is do they need the Mastercam MILL 3D package or is MILL 2D the appropriate package for them? The answer to this question most often times comes down to the type of parts that the customer currently works with. Here is a quick breakdown of part types better suited for each package:

PARTS TO TARGET WITH MILL 2D:

Simple 2D shapes: Parts that are simple in design, such as plates, brackets, and flanges, can be easily machined using Mill 2D.

Sheet metal parts: Sheet metal parts are typically 2D and require operations such as punching and cutting, which are well-suited for Mill 2D.

PCBs: Printed circuit boards (PCBs) are flat and require drilling and routing, which can be accomplished using Mill 2D.

Stamped parts: Stamped parts require precise holes and cutouts, which can be achieved with Mill 2D.

PARTS BETTER SUITED FOR MILL 3D:

Mold and die components: Creating complex mold and die components often requires 3D machining operations, which can be efficiently accomplished using Mill 3D.

Aerospace components: Parts used in the aerospace industry often have complex shapes and require advanced machining techniques, such as 5-axis machining, which is supported by Mill 3D.

Medical implants: Medical implants, such as hip and knee replacements, require intricate 3D shapes and precise machining, which can be achieved with Mill 3D.

Automotive parts: Automotive parts, such as engine components and transmission parts, often have complex shapes and require precise machining, which is supported by Mill 3D.

As always, you can contact our team directly HERE!